What you can do with a laser in model making.

2023年 8月 5日0

Laser machines are versatile tools that offer numerous possibilities in model making. They can be used for cutting, engraving, and etching various materials, allowing for the creation of intricate and detailed components. Here are some applications of lasers in model making:

- Cutting materials: Laser machines can precisely cut a wide range of materials, including wood, acrylic, cardboard, paper, and various plastics. This enables you to create clean, smooth-edged components for assembling your model.

- Engraving and etching: Laser machines can engrave and etch patterns, text, or images onto surfaces of different materials. This technique can be used to add details, textures, or branding to your model components.

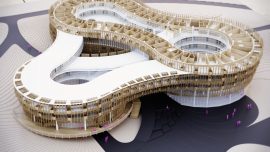

- Creating complex geometries: Laser machines enable you to create complex geometries and intricate designs that may be challenging or impossible to achieve with traditional cutting methods. This allows for greater creativity and innovation in your models.

- Fabricating modular components: Laser machines can be used to create modular components, which can be easily assembled and disassembled. This is particularly useful for large-scale models, exhibitions, or design iterations.

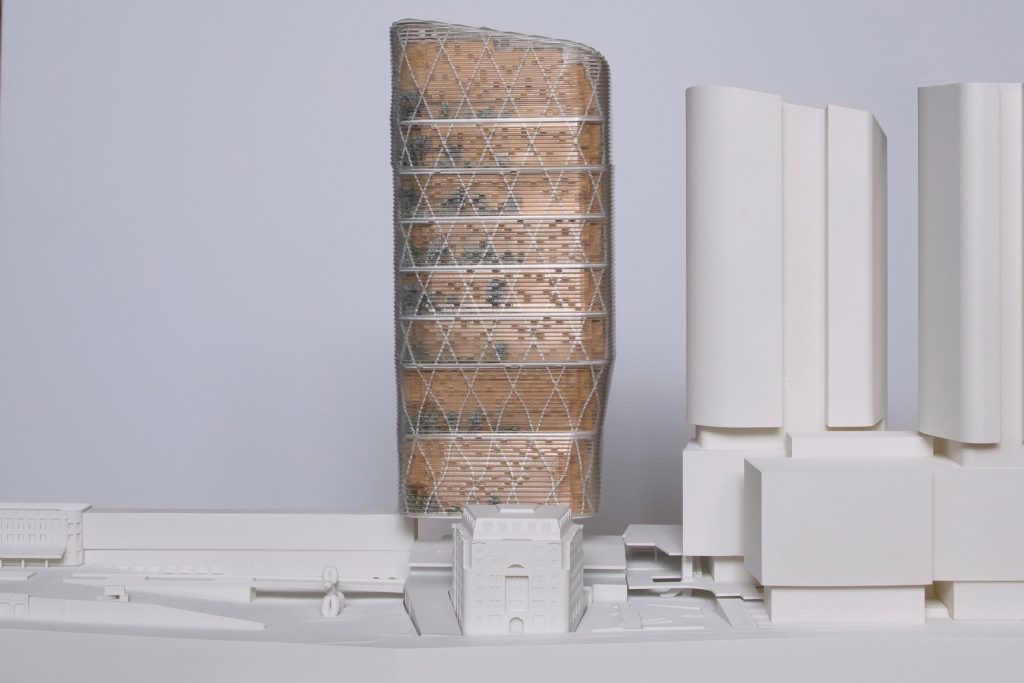

- Producing scale models: Laser machines are ideal for creating precise scale models of architectural designs, vehicles, machinery, or other objects. The high level of accuracy and detail offered by laser machines ensures that your scale models are faithful representations of the original designs.

- Prototyping: Lasers can be used for rapid prototyping, allowing you to quickly create and test various design concepts and iterations. This enables you to refine and optimize your model before committing to a final design.

- Customization: Laser machines allow for easy customization of model components, enabling you to tailor your model to specific requirements, preferences, or branding.

- Creating molds and templates: Laser machines can be used to create molds and templates for casting, vacuum forming, or other fabrication processes. This allows you to produce multiple identical components for your model.

- Layering and stacking: Lasers can be used to create thin, precise layers or components that can be stacked or layered to create intricate, three-dimensional models or structures.

- Light and shadow effects: By using laser-cut components with varying levels of opacity or translucency, you can create interesting light and shadow effects in your models, enhancing their visual impact.

These are just a few examples of what you can do with a laser machine in model making. The versatility and precision of laser machines make them an invaluable tool for creating detailed, professional models that effectively convey your design ideas and concepts.

0 comments

Write a comment