Model making capabilities

Model making capabilities refer to the skills, techniques, and resources available to create a wide range of models for various purposes. These capabilities encompass the use of different materials, tools, and methods to produce high-quality, accurate, and visually appealing models. Here are some key model making capabilities:

- Understanding scales: Model makers need to be proficient in working with different scales, depending on the size and purpose of the project. They should be able to accurately measure and reproduce elements in the chosen scale to ensure consistency and realism.

- Material knowledge: Model makers must be familiar with a wide range of materials, including foam board, cardboard, balsa wood, basswood, acrylic, and plastics. They should understand the properties and limitations of each material and be able to select the best option for a specific project.

- Cutting and shaping techniques: Model makers should be skilled in various cutting and shaping techniques, using tools such as hobby knives, scissors, and saws to create precise and clean cuts. They should also be able to shape materials using sanding, carving, or bending methods.

- Assembly and construction: Model makers need to be proficient in assembling and constructing models, ensuring that connections are strong, accurate, and aesthetically pleasing. They should be able to work with different types of adhesives and fasteners and understand the best method for each material and application.

- Detailing and finishing: Model makers must be skilled in adding details and finishes to their models, such as windows, doors, cladding, and paint. They should be able to create realistic and accurate representations of these elements using various techniques, tools, and materials.

- Landscape and context elements: Model makers should be capable of creating landscape and context elements, such as trees, plants, roads, and neighboring buildings, to provide a complete and accurate representation of the project in its surroundings.

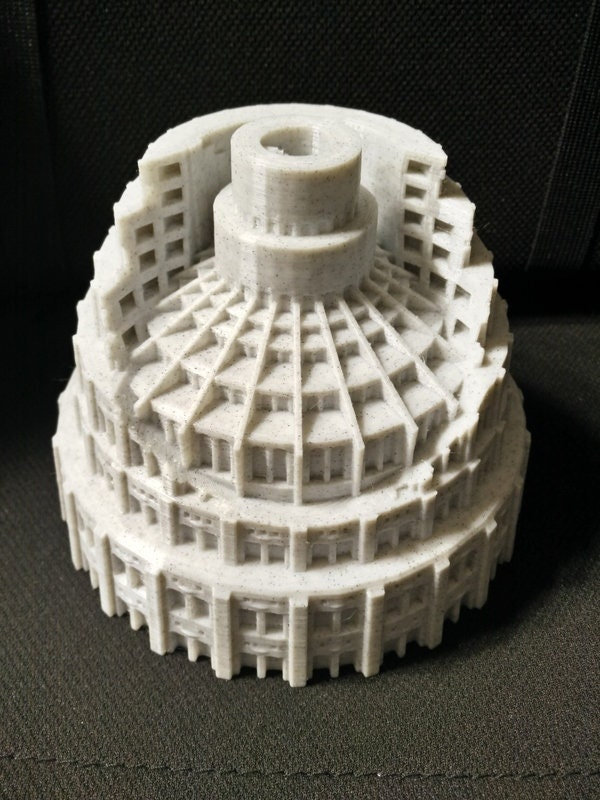

- Digital fabrication: In some cases, model makers may use digital fabrication techniques, such as 3D printing, laser cutting, or CNC milling, to create parts or entire models. They should be familiar with these technologies and understand their applications and limitations.

- Presentation and photography: Model makers need to have a good understanding of presentation and photography techniques to showcase their models effectively. This includes lighting, positioning, and background selection to create visually appealing and informative displays.

Developing and refining these model making capabilities is essential for professionals in the field to create high-quality, accurate, and visually appealing models that effectively communicate their ideas and concepts to clients, stakeholders, or team members.

0 комментариев

Написать комментарий